Three Common Repair Methods for Bearings

Source: China Bearing Network | Time: 2013-08-08

When a bearing starts to show signs of wear or malfunction, the first thought should be to repair it rather than replace it immediately. Today, we will explore three common and effective repair methods used in modern SKF bearings. 1. **Fault Repair**: This method is applied when a bearing is already experiencing issues. The process involves identifying the problem, stopping the operation, and performing necessary repairs to restore the bearing’s functionality. 2. **Scheduled Repair**: Based on the design specifications and operational experience, this approach involves setting a regular maintenance schedule. It ensures that the bearing continues to operate smoothly by performing preventive maintenance at predetermined intervals. 3. **Predictive Repair**: Utilizing advanced SKF bearing diagnostic techniques, this method allows real-time monitoring of the bearing's condition. By detecting early signs of failure, engineers can take action before any serious damage occurs, minimizing downtime and costs. During operation, bearings often exhibit certain symptoms such as unusual noises, increased temperature, or vibrations. These signs can be detected through various means—listening, touching, visual inspection, and using specialized fault diagnosis tools. Identifying these changes helps determine whether the bearing is still functioning properly or requires immediate attention. Regular maintenance and timely intervention are essential to extend the lifespan of bearings and ensure the smooth operation of machinery. Whether you're dealing with industrial equipment, automotive systems, or heavy machinery, understanding these repair methods can help you make informed decisions and avoid costly failures.

Recommended for You: - NSK Bearing Prefix Codes: How to Open Device Oscillation Motor Bearings - KOYO Rolling Bearings: "Collection of Correct Installation Methods" - Analysis of Bearings in Centrifugal Compressors and Railway Locomotives This article is linked from http:// Please indicate the source: China Bearing Network http://

Previous: Analysis of Bearing Condition and Reuse Next: Common Knowledge About Bearing Overheating

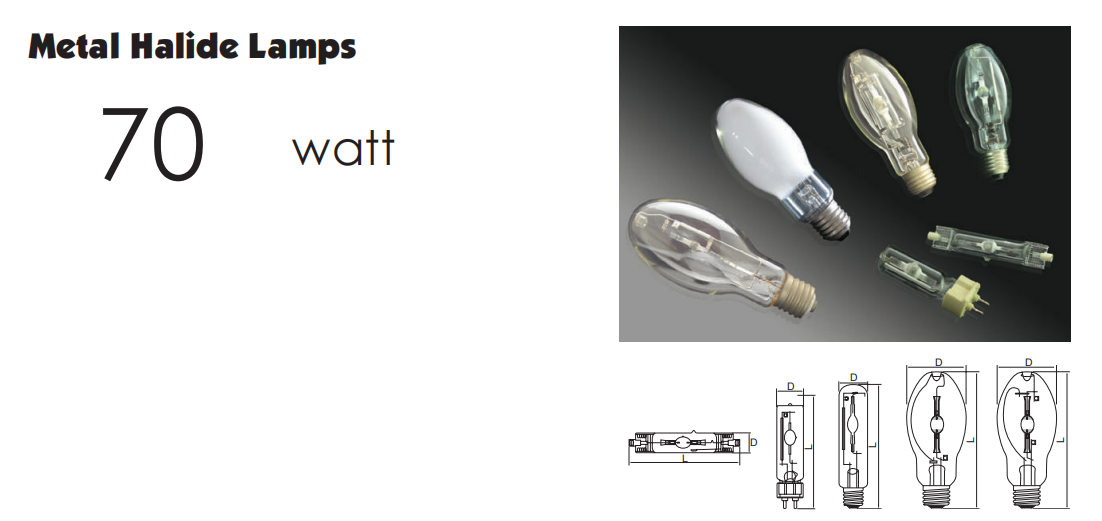

Metal Halide Bulb

A Metal Halide Bulb, also known as a Metal Halide Lamp, is a type of gas discharge lamp that produces light by passing electrical currents through a mixture of mercury and metal halides. It is known for its high luminous efficacy, long lifespan, and good color rendering index, making it a popular choice for various industrial and commercial applications

4

Key Features

- High Luminous Efficacy: Achieves light efficacy ranging from 65 to 140 lm/W.

- Long Lifespan: Typically lasts between 5000 to 20,000 hours.

- Good Color Rendering: Provides a high color rendering index (Ra) of 65 to 95, offering accurate color representation.

- Compact and Stable Design: Available in quartz and ceramic versions, offering structural stability and durability.

Applications

Metal Halide Bulbs are widely used in:

- Stadiums and Sports Arenas: For their high output and ability to provide optimal lighting conditions.

- Construction Sites: Ensuring safety and visibility during nighttime operations.

- Parking Lots and Loading Docks: Providing bright, consistent lighting for extended periods.

- Commercial Buildings: Enhancing the aesthetic appeal and functionality of indoor spaces

.7

metal halide bulb,400 watt metal halide bulb,250 watt metal halide bulb,1000 watt bulb,100 watt metal halide bulb

Yangzhou M.T. New Energy & Lighting Group Co., Ltd. , https://www.mtstreetlight.com