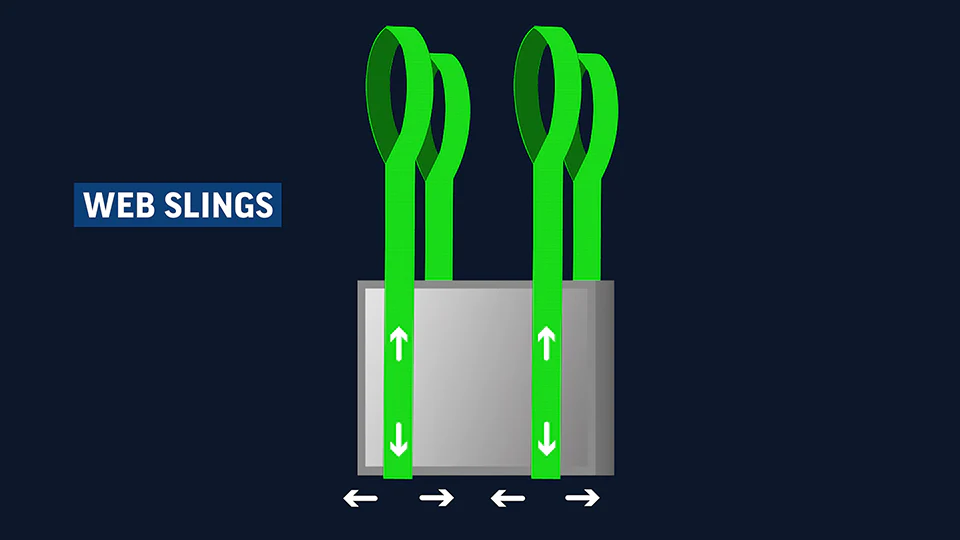

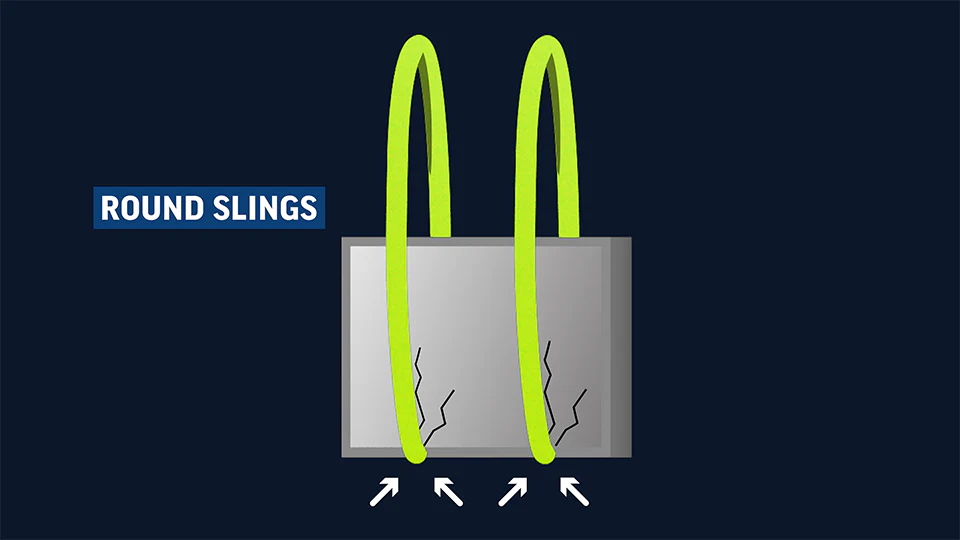

THOR-TEX synthetic slings play a crucial role in a wide range of lifting tasks. Known for their strength, lightness, and ease of storage, they are indispensable tools for many industries. However, depending on the specific scenario, one type of sling might be more suitable than another. In this article, we’ll explore the advantages and disadvantages of using round slings versus web slings. THOR-TEX web slings are composed of woven polyester fibers with eyes sewn into each end. These eyes come in various configurations, such as reinforced eyes (with bearing points lined with Cordura), twisted eyes, and flat or tapered eyes. Although both THOR-TEX web and round slings are made from the same polyester fibers, web slings tend to stretch slightly more than round slings due to their woven structure. This characteristic makes them ideal for supporting objects from underneath, particularly those that are oddly shaped or fragile. Consider an example where the object being moved is a piece of machinery with delicate side panels. A web sling is perfect for this situation since it can be positioned under the machinery without causing creases or pressure points, spreading the load evenly across the width of the webbing. However, web slings may not be the best option if there’s a risk of abrasion, as all the polyester fibers are exposed along the entire length of the sling. Furthermore, creasing the sling over a small attachment point can lead to damage. Therefore, in situations involving small, permanent attachment points, it's advisable to switch to a round sling. THOR-TEX round slings are crafted from two layers of polyester. The inner layer consists of continuous strands of load-bearing polyester protected by a woven polyester jacket. This design offers excellent resistance to abrasion, crushing, and foreign particles while maintaining a low stretch factor. Its flexibility and strength-to-size ratio make it ideal for tight spaces and small lift points. Round slings excel in scenarios where creasing is a concern, as the load-bearing polyester fibers within the outer jacket can conform and mold around various types of lift points, particularly those designated by the manufacturer. On the other hand, round slings may not be the best choice when moving machinery without fixed lifting points and fragile corners or side panels. Since the majority of the weight is concentrated in the group of polyester fibers, there is little-to-no distribution of weight when lifting from beneath, potentially causing damage to the item. In these cases, swapping out the round sling for a web sling is recommended. For further insights into synthetic lifting slings, click here. For more details about THOR-TEX web slings, read our safety bulletin here. Remember, selecting the right sling depends on the specific requirements of your lifting task. Whether you need a web sling or a round sling, understanding their unique properties will help ensure safe and efficient operations. auto parts Hebei Yuanyue Trading Co.,Ltd , https://www.hbyuanyue.com

Advantages and Disadvantages of Web Slings

Advantages and Disadvantages of Round Slings

Web Sling or Round Sling?