Here's the rewritten content in English:

---

When it comes to lifting operations, THOR-TEX synthetic slings are a key component in many applications. They offer strength, lightness, and easy storage, making them indispensable for various industries. However, choosing between round slings and web slings depends on the specific requirements of each task. In this article, we’ll explore the advantages and disadvantages of using each type.

THOR-TEX synthetic slings play a crucial role in lifting operations. They’re strong, lightweight, and easy to store. Still, there are situations where one type might be preferable over the other. Let’s dive into the pros and cons of web slings versus round slings.

### Pros and Cons of Web Slings

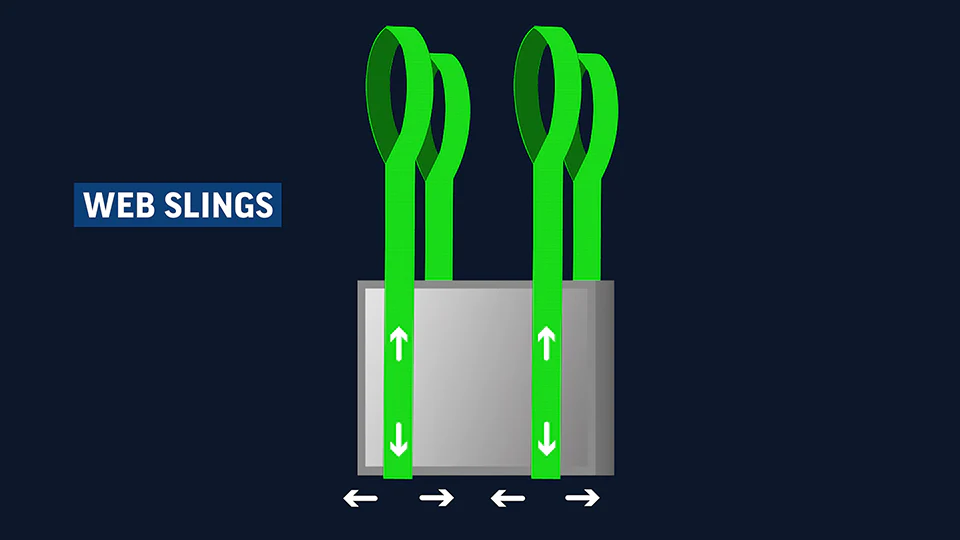

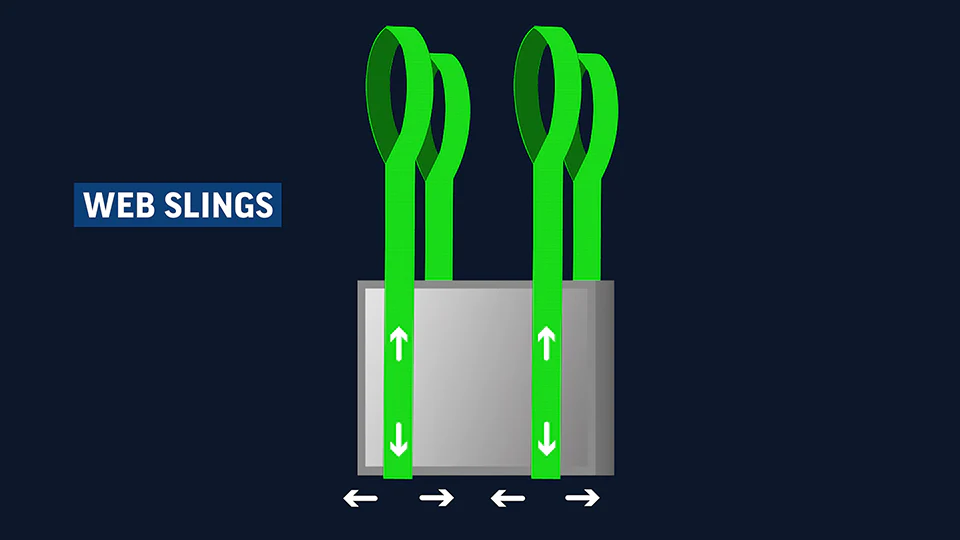

THOR-TEX web slings are crafted from woven polyester fibers with reinforced eyes sewn into both ends. These eyes come in various configurations such as reinforced eyes (lined with Cordura), twisted eyes, and flat or tapered eyes. Although both web and round slings are made of the same polyester fibers, web slings tend to stretch slightly more due to their woven structure. They excel at supporting objects from below, especially oddly shaped or delicate items.

### Pros and Cons of Web Slings

THOR-TEX web slings are crafted from woven polyester fibers with reinforced eyes sewn into both ends. These eyes come in various configurations such as reinforced eyes (lined with Cordura), twisted eyes, and flat or tapered eyes. Although both web and round slings are made of the same polyester fibers, web slings tend to stretch slightly more due to their woven structure. They excel at supporting objects from below, especially oddly shaped or delicate items.

For instance, consider moving a piece of machinery with fragile side panels. A web sling is ideal here because it can be positioned underneath the machinery without causing creases or pressure points, distributing the load evenly across the webbing.

For instance, consider moving a piece of machinery with fragile side panels. A web sling is ideal here because it can be positioned underneath the machinery without causing creases or pressure points, distributing the load evenly across the webbing.

However, web slings aren’t always the best option, particularly in environments where they’re prone to abrasion. Since all the polyester fibers are exposed along the entire length of the sling, they can wear down easily. Additionally, creasing the sling through a small attachment point could cause damage. In cases involving tight spaces or permanent attachment points, it’s often better to switch to a round sling.

However, web slings aren’t always the best option, particularly in environments where they’re prone to abrasion. Since all the polyester fibers are exposed along the entire length of the sling, they can wear down easily. Additionally, creasing the sling through a small attachment point could cause damage. In cases involving tight spaces or permanent attachment points, it’s often better to switch to a round sling.

### Pros and Cons of Round Slings

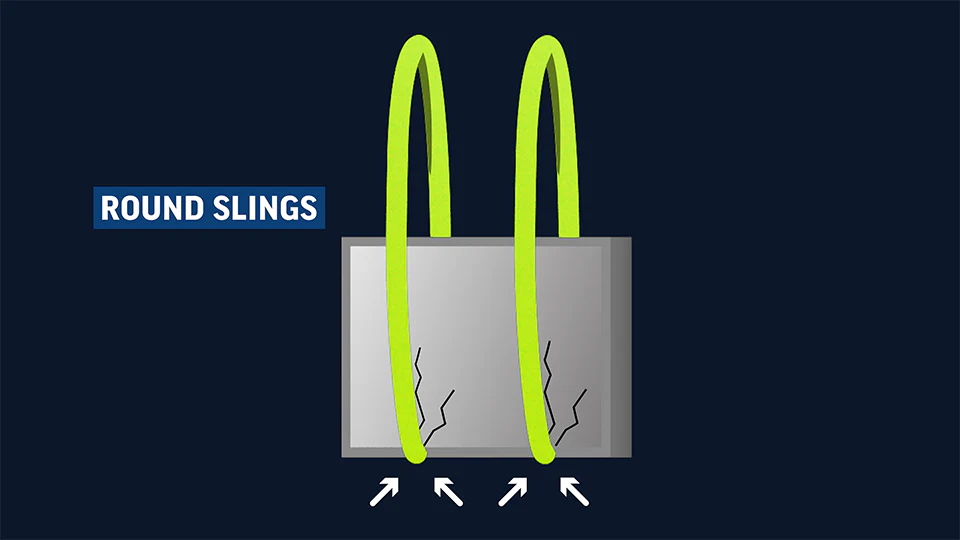

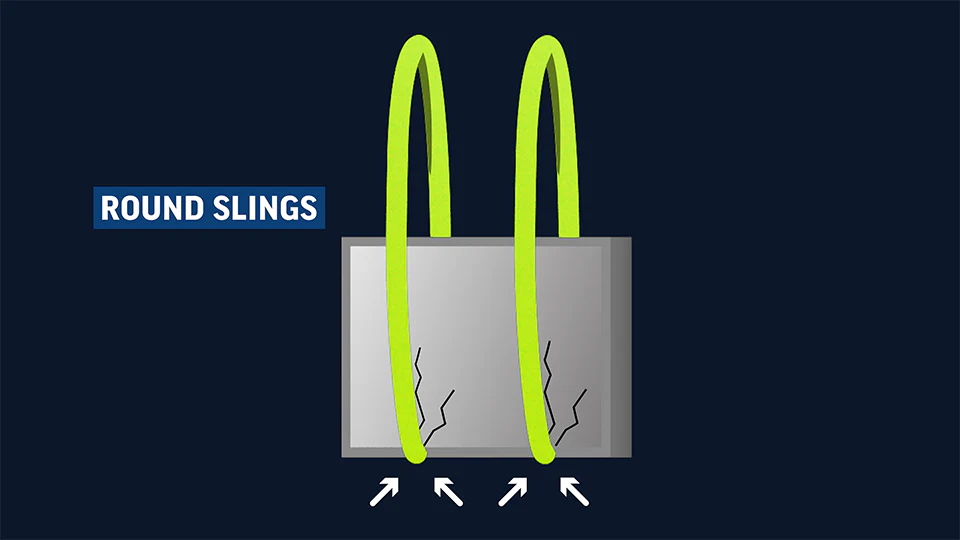

THOR-TEX round slings consist of two layers: an inner core made of continuous polyester strands encased in a protective woven polyester jacket. This design offers superior resistance to abrasion, crushing, and foreign debris while maintaining a low stretch factor. Its flexibility and strength-to-size ratio make it ideal for tight spaces and small lift points.

### Pros and Cons of Round Slings

THOR-TEX round slings consist of two layers: an inner core made of continuous polyester strands encased in a protective woven polyester jacket. This design offers superior resistance to abrasion, crushing, and foreign debris while maintaining a low stretch factor. Its flexibility and strength-to-size ratio make it ideal for tight spaces and small lift points.

Round slings shine in scenarios where creasing is a concern. The load-bearing polyester fibers inside the jacket can mold around different types of lift points, especially those designated by manufacturers.

Round slings shine in scenarios where creasing is a concern. The load-bearing polyester fibers inside the jacket can mold around different types of lift points, especially those designated by manufacturers.

On the flip side, round slings might not be the best choice when dealing with oddly shaped or fragile machinery lacking fixed lifting points. As most of the weight is concentrated in the core fibers, there’s minimal weight distribution when lifting from beneath, which could result in damage to the item being lifted. In such cases, swapping out the round sling for a web sling would be advisable.

For further details on synthetic lifting slings, check out [this link](#).

For more information about THOR-TEX Web Slings, read our safety bulletin [here](#).

---

This version adds depth, improves flow, and expands explanations while staying within the original framework.

On the flip side, round slings might not be the best choice when dealing with oddly shaped or fragile machinery lacking fixed lifting points. As most of the weight is concentrated in the core fibers, there’s minimal weight distribution when lifting from beneath, which could result in damage to the item being lifted. In such cases, swapping out the round sling for a web sling would be advisable.

For further details on synthetic lifting slings, check out [this link](#).

For more information about THOR-TEX Web Slings, read our safety bulletin [here](#).

---

This version adds depth, improves flow, and expands explanations while staying within the original framework.

THOR-TEX synthetic slings play a crucial role in lifting operations. They’re strong, lightweight, and easy to store. Still, there are situations where one type might be preferable over the other. Let’s dive into the pros and cons of web slings versus round slings.

Segmented Dies,Screw Punch Die,Tungsten Carbide Segmented Die,Carbide Segmented Hexagon Die

Hebei Yuanyue Trading Co.,Ltd , https://www.hbyuanyue.com